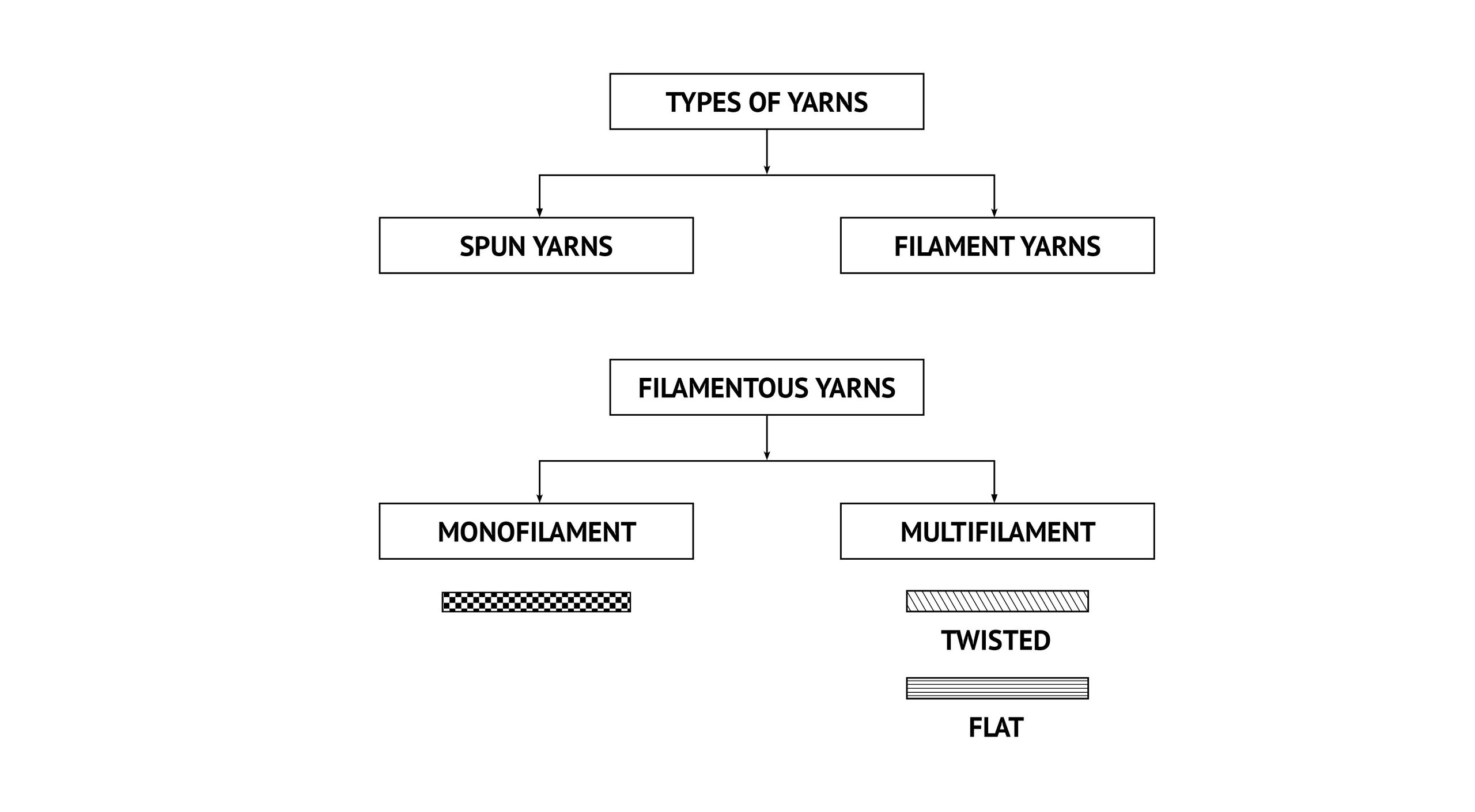

YARN TYPES

Spun yarns

Spun Yarns are made from short length fibers. Its short fibers are twisted into continuous strands with protruding ends. They are more absorbent, used oftenly in more complex manufacturing processes. Its sizes are often expressed in yarn number, according to the amount of twist used. These spun fibers have low tensile strength and a large surface area. Particle retention is excellent, though cake release is typically poor.

Filament yarns

Filament Yarns are made from long length filament fibers and fabrics. It has long continuous fibers with packed strands, usually with very low or very high twist. Its absorbency depends on fiber content, and it is used in less complicated manufacturing processes.

MULtifilament yarns

Multifilament yarns are produced by the continuous extrusion of synthetic resins. The filament bunches are twisted together to one strain. Increased twisting will reduce particle retention within the yarn structure, while also decreasing collection efficiency. Multifilament yarns have high tensile strength and average particle collection efficiency, so filter cake release is average.

Monofilament yarns

Monofilament yarns are single heavier extrusions. These extrusions are smooth with high tensile strength. Monofilament yarn has excellent cake release properties and resistance to particle retention, and low particle collection efficiency.